smert

Well-Known Member

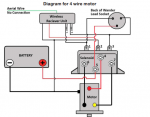

I have a reversing solenoid and remote control from Winchmax, and I tried wiring it up today.

The diagram it came with has options for winch motors with 4 terminals or 2 terminals. My winch motor has 3!

I worked out the +ve and -ve supply and the output switches when the remote is activated so I figured I could connect it to the motor. I connected one of outputs from the solenoid to the motor and it worked perfectly. I then connected the other output and the motor would only turn very slowly and the breaker tripped after a while. The wires from the solenoid were getting warm too although they are chunky enough to handle the current.

Any ideas what is going on and why?

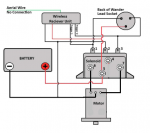

The diagram it came with has options for winch motors with 4 terminals or 2 terminals. My winch motor has 3!

I worked out the +ve and -ve supply and the output switches when the remote is activated so I figured I could connect it to the motor. I connected one of outputs from the solenoid to the motor and it worked perfectly. I then connected the other output and the motor would only turn very slowly and the breaker tripped after a while. The wires from the solenoid were getting warm too although they are chunky enough to handle the current.

Any ideas what is going on and why?