Tanqueray

Well-Known Member

Does anyone know of any wheelhouse moulds kicking about or somebody who can produce mouldings for me?

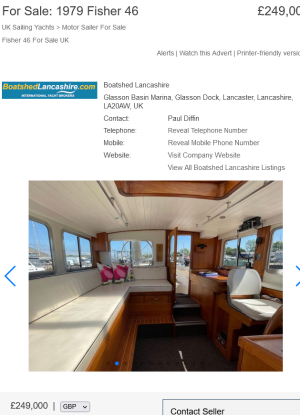

Something along the lines of a Fisher 46 or Rhea 850 is the sort of thing I'm after. It's a one-off project and I can laminate / modify myself if required or someone can just work with me on the design and then produce the mouldings.

Pm if you like. Ta.

(Yes, I can do it the long way round but I'm looking for a short-cut to speed things up if poss).

Something along the lines of a Fisher 46 or Rhea 850 is the sort of thing I'm after. It's a one-off project and I can laminate / modify myself if required or someone can just work with me on the design and then produce the mouldings.

Pm if you like. Ta.

(Yes, I can do it the long way round but I'm looking for a short-cut to speed things up if poss).