MYStargazer

Well-Known Member

I'm looking to remount my Houdini hatch onto a curved GRP deck. It can't go straight on as the curve's too tight.

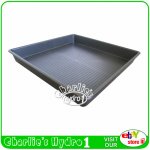

I was thinking of using one of these plastic trays as a female mold, to make a raised section, then cutting away the molding to fit the curved deck, then glassing into place on the inside to leave a neat join when seen from the exterior. The trouble is that this plastic tray is 60cm x 60cm x 7cm, and is just too small.

as a female mold, to make a raised section, then cutting away the molding to fit the curved deck, then glassing into place on the inside to leave a neat join when seen from the exterior. The trouble is that this plastic tray is 60cm x 60cm x 7cm, and is just too small.

Can anyone think of an alternative everyday item to use as a female mold instead? The next largest size for this product is 100cm x 100cm which will be too big...

I was thinking of using one of these plastic trays

as a female mold, to make a raised section, then cutting away the molding to fit the curved deck, then glassing into place on the inside to leave a neat join when seen from the exterior. The trouble is that this plastic tray is 60cm x 60cm x 7cm, and is just too small.

as a female mold, to make a raised section, then cutting away the molding to fit the curved deck, then glassing into place on the inside to leave a neat join when seen from the exterior. The trouble is that this plastic tray is 60cm x 60cm x 7cm, and is just too small.Can anyone think of an alternative everyday item to use as a female mold instead? The next largest size for this product is 100cm x 100cm which will be too big...