damonlm

New Member

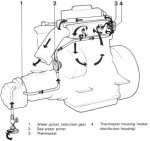

In November 2018 I purchased a 1984 Dufour 2800 that was fitted with the original Volvo MD7A. This has been running absolutely fine, albeit with a little white smoke under moderate to hard throttle. A couple of weeks ago on a trip out, I noticed significant more smoke and a lot less water flow than I’m used to seeing. I have very little mechanical experience so turned to the internet and forums for suggestions. The impellor was checked and all looked fine. I read on lots of sites how the water channels through the exhaust manifold get clocked up so I set about removing this to inspect further. To my amazement, 2 of the 3 water channels were completely blocked with the third more than 50% restricted. Having read a very detailed blog about someone flushing one of these engines, I purchased some Rydlyme Marine descaler, various hoses and a submersible pump. A bucket of the Rydlyme solution was then pumped through the tube from the inlet seacock; I bypassed the water pump with some flexi house and plugged the bypass hole within the thermostat housing to make sure the solution went around the engine. I had to modify the existing thermostat to do this and replaced it in the housing to get a watertight seal. The return to the bucket came from the top of the exhaust block. I ran the solution both ways around the engine for 2 hours each way. The results were amazing.

Ironically, once refitting a new thermostat and reconnecting the relevant pipes. Very little water was still coming out of the exhaust. It turned out to be a blocked water inlet seacock. This was an easy fix and considering 2.5 of the 3 channels were blocked in the exhaust block, I consider the flush a good job to have still done.

One of my questions is does anyone know what and where the 3 holes in the exhaust block go / do and what the function of the 2 inlet pipes into the block do? One is via a T piece underneath the block and the other through the various routes in the thermostat housing cover.

My second question is what advice would people give if rebuilding one of these engines. I’ve just managed to pick up another MD7A that I’ve seen running. My plan was to strip it completely and rebuild it. Partly for fun and to learn what’s actually in there and secondly to have a ‘good’ engine ready should anything ever happen to the one currently fitted. What tests and tolerances would people recommend I check both before and during the strip / rebuild and how might these results affect my actions. I’ve read things such as compression checks, reseating valves, skimming heads, reboring and cylinders rehoned but don’t know if these are things you should do anyway or only if some tolerance is out etc. Any general advice with this would be greatly appreciated.

Many thanks,

Damon

Ironically, once refitting a new thermostat and reconnecting the relevant pipes. Very little water was still coming out of the exhaust. It turned out to be a blocked water inlet seacock. This was an easy fix and considering 2.5 of the 3 channels were blocked in the exhaust block, I consider the flush a good job to have still done.

One of my questions is does anyone know what and where the 3 holes in the exhaust block go / do and what the function of the 2 inlet pipes into the block do? One is via a T piece underneath the block and the other through the various routes in the thermostat housing cover.

My second question is what advice would people give if rebuilding one of these engines. I’ve just managed to pick up another MD7A that I’ve seen running. My plan was to strip it completely and rebuild it. Partly for fun and to learn what’s actually in there and secondly to have a ‘good’ engine ready should anything ever happen to the one currently fitted. What tests and tolerances would people recommend I check both before and during the strip / rebuild and how might these results affect my actions. I’ve read things such as compression checks, reseating valves, skimming heads, reboring and cylinders rehoned but don’t know if these are things you should do anyway or only if some tolerance is out etc. Any general advice with this would be greatly appreciated.

Many thanks,

Damon