pcatterall

Well-Known Member

The valves on my 2 recently dismantled Perkins 4108s had little O ring seals in a groove on the 4 inlet valves. ( no seals or grooves on the exhaust valve stems)

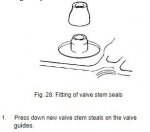

Parts4engines supplied a kit containing the 4 O rings but also 8 little cup shaped seals described as valve stem oil seas.

I can't immediately see just where to fit them on the stem( but perhaps more investigation will reveal this)

I cannot see them on the diagram in the manual, nor are they mentioned in the text.

Can anyone shed light on this please. It would be interesting to learn more about oil 'movement' between the engine and head generally. I see that other Perkins

engines do not use these cup type oil seals but just the O rings on the inlets.

Would welcome info on where if anywhere I should fit these cups, I don't want to get it wrong and have bits of disintegrating rubber flying around the head.

The O rings were also interesting in that they must have to stand a lot of wear and heat.

Parts4engines supplied a kit containing the 4 O rings but also 8 little cup shaped seals described as valve stem oil seas.

I can't immediately see just where to fit them on the stem( but perhaps more investigation will reveal this)

I cannot see them on the diagram in the manual, nor are they mentioned in the text.

Can anyone shed light on this please. It would be interesting to learn more about oil 'movement' between the engine and head generally. I see that other Perkins

engines do not use these cup type oil seals but just the O rings on the inlets.

Would welcome info on where if anywhere I should fit these cups, I don't want to get it wrong and have bits of disintegrating rubber flying around the head.

The O rings were also interesting in that they must have to stand a lot of wear and heat.