TSailors

Well-Known Member

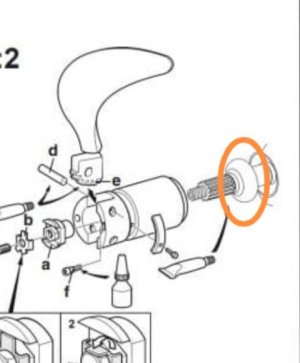

Hi. Seeing that the anode (and part of the sail drive) is shot, I thought I'd remove the anode, which depends on me removing the propeller it seems.

The anode nor the propeller has any screws visible from outside, apart from the 3 allens that I removed when removing the blades.

So far I removed the 3 blades, and the central screw of the propeller.

However, it won't slide off. I noticed a crescent-shaped washer/locker inside, I think that's what holding it in place. How can I remove that?

Many thanks, -t

The anode nor the propeller has any screws visible from outside, apart from the 3 allens that I removed when removing the blades.

So far I removed the 3 blades, and the central screw of the propeller.

However, it won't slide off. I noticed a crescent-shaped washer/locker inside, I think that's what holding it in place. How can I remove that?

Many thanks, -t