Rhylsailer99

Well-Known Member

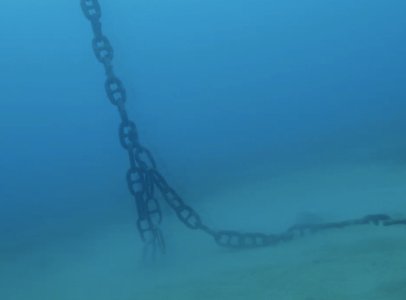

I had a sleave over my chain, and I was shocked to see the difference after 2 years of the section not in the sleave.

sleaved section still measures over 10mm, but the unsleaved chain is pitted and measures only 9.4mm.

I was told the sleave might cause the chain to rust more, but as you can see it offers better protection.

sleaved section still measures over 10mm, but the unsleaved chain is pitted and measures only 9.4mm.

I was told the sleave might cause the chain to rust more, but as you can see it offers better protection.