tudorsailor

Well-Known Member

I currently have an adjustable topping lift that is wire from the mast down to a block and then braid on braid to the clutch in the cockpit

I would like to change as the wire is old and plastic covered. One option is to use dyneema instead of the wire. Am I right that I ought to have a thimble in the soft eye of the 5mm dyneema so maintain the strength of the dyneema by keeping a big radius.

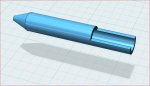

If I am, would a standard thimble do or do I need one of the things from Colligo http://www.colligomarine.com/shop-all/terminator-7-9mm-open-black-1

Thanks

TudorSailor

I would like to change as the wire is old and plastic covered. One option is to use dyneema instead of the wire. Am I right that I ought to have a thimble in the soft eye of the 5mm dyneema so maintain the strength of the dyneema by keeping a big radius.

If I am, would a standard thimble do or do I need one of the things from Colligo http://www.colligomarine.com/shop-all/terminator-7-9mm-open-black-1

Thanks

TudorSailor