PCUK

Well-Known Member

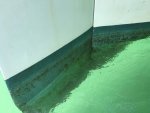

Has anybody used this product from Reactive Resins as yet? Application seems far easier than other epoxy based types with a much wider inter-coat window and it doesn't need abrading before launch. I'm going to give it a try but wondered if there were any other users here to offer comments.