kittan

New Member

I have had the engine out of the boat for repairs and as the time comes to put it back in I am reflecting on the anode bonding system, which has always been 'as is' since buying the boat ten years ago. While I have good access to the anode studs etc I am just looking for a second opinion on whether I should keep on the same course.

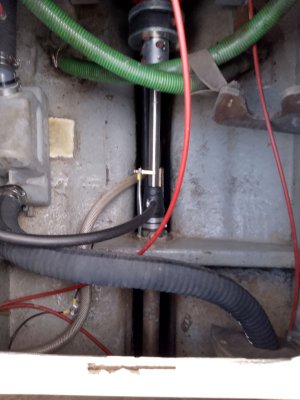

So what is in the electro-galvanic mix? The hull is mahogany planking with copper fastenings, iron keel, iron straps on the wooden rudder, stainless steel prop shaft, bronze propeller, bronze stern tube, bronze skin fittings. There is a flex drive between the gearbox and prop shaft so the shaft and prop are electrically isolated. There are two anodes on the rudder, and one anode on the hull, which is bonded to the stern tube, and also bonded to the engine bed which is a common 12VDC negative connection point. The engine alternator's -ve path is through the engine block, so it is also connected to the engine bed via the battery negative (although it is on flex mounts so would otherwise be electrically isolated). I don't have an AC system or shorepower connection.

There isn't space on the shaft for a shaft anode, but there is line of sight from the prop to the two rudder anodes.

I cannot see the point of the bonding connection between the hull anode and the engine bed, as the engine bed isn't electrically connected to anything in the water. If I made a connection across the shaft coupling it would connect the shaft and propeller to the anode, but it would also connect them to the battery negative circuit which I have read is something to avoid. I think the only way I can avoid this would be installing brushes on the shaft.

As the stern tube is bronze, and painted every season, it isn't obvious that it even needs anode protection (and the associated risk of timber damage).

My planned change is to remove the connection between the hull anode and the engine bed, on the basis that it isn't protecting anything but it is creating a path from battery negative to the stern tube. The more radical option is to remove the hull anode. as it has caused some localised damage to the planking (which I have repaired). Would appreciate thoughts on both options as well as any others- although I only have 48 hours to decide!

So what is in the electro-galvanic mix? The hull is mahogany planking with copper fastenings, iron keel, iron straps on the wooden rudder, stainless steel prop shaft, bronze propeller, bronze stern tube, bronze skin fittings. There is a flex drive between the gearbox and prop shaft so the shaft and prop are electrically isolated. There are two anodes on the rudder, and one anode on the hull, which is bonded to the stern tube, and also bonded to the engine bed which is a common 12VDC negative connection point. The engine alternator's -ve path is through the engine block, so it is also connected to the engine bed via the battery negative (although it is on flex mounts so would otherwise be electrically isolated). I don't have an AC system or shorepower connection.

There isn't space on the shaft for a shaft anode, but there is line of sight from the prop to the two rudder anodes.

I cannot see the point of the bonding connection between the hull anode and the engine bed, as the engine bed isn't electrically connected to anything in the water. If I made a connection across the shaft coupling it would connect the shaft and propeller to the anode, but it would also connect them to the battery negative circuit which I have read is something to avoid. I think the only way I can avoid this would be installing brushes on the shaft.

As the stern tube is bronze, and painted every season, it isn't obvious that it even needs anode protection (and the associated risk of timber damage).

My planned change is to remove the connection between the hull anode and the engine bed, on the basis that it isn't protecting anything but it is creating a path from battery negative to the stern tube. The more radical option is to remove the hull anode. as it has caused some localised damage to the planking (which I have repaired). Would appreciate thoughts on both options as well as any others- although I only have 48 hours to decide!