GerardV

New Member

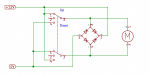

This week I found out that the anchor winch solenoid (winch relay 200Ampere) have broke down. More specific the issue being the “anchor lift” contacts. I assume that the cause of this problem is that the contacts have ‘burned in’ due to transient power surges when switching off the relay.

Power surges are common with inductive loads such as the DC electro motor of the winch.

Soon I will install a new solenoid (a 500 Ampere type). Naturally I want to prevent this from happening again.

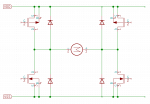

Does anybody has experience with installing varistors parallel over the contacts of a anchor winch solenoid? Or other devices such as transient suppressor diodes?

For ‘fun’ I contacted the well known manufacturer of the anchor winch. The answer was that they tested 500 of these solenoids and never had an issue. I was the first one .......

.......

Power surges are common with inductive loads such as the DC electro motor of the winch.

Soon I will install a new solenoid (a 500 Ampere type). Naturally I want to prevent this from happening again.

Does anybody has experience with installing varistors parallel over the contacts of a anchor winch solenoid? Or other devices such as transient suppressor diodes?

For ‘fun’ I contacted the well known manufacturer of the anchor winch. The answer was that they tested 500 of these solenoids and never had an issue. I was the first one