superheat6k

Well-Known Member

So today I have attempted to set up the RPM inputs into my engine protection system, and it ain't working !

I am using a Pulse to Analogue convertor rated for 0 - 1 kHz to 0 - 10vdc, and have roughly worked out that at max display revs of 3,000 RPM to expect a pulse frequency ~ 750 hz.

But when I run the engine at idle ~ 750 RPM I am seeing close to max revs voltage ~ 10vdc, and not the voltage I would expect ~ 2.5vdc

Going back to basics I need to know the Pole pair (N + S) quantity and Pulley ratio.

So can anyone tell me the common pole count for a typical ~ 90a marine duty alternator - or specifically as in my case as fitted to Cummins 6BT5.9M engines. Lots of general information available on alternators, but nowhere does it state the specifics of how many poles. I can strip the alternator and count the pole tabs on the rotor, but prefer not to do this.

6 seems to be fairly standard, but possibly 5 or even 8. None of these values explain why I am seeing such a high output.

I can work out the pulley ratio from the OD measurement of each pulley, but even this detail is not listed anywhere. My guestimate is based upon a Pulley ratio of 2.5 and a Pole count of 6.

I have found out the voltage to expect on the signal pulse is ~16 volts ac (RMS) so a peak value ~23vac. I am wondering if the signal is simply too strong or too noisy and is why I am seeing a corrupted output.

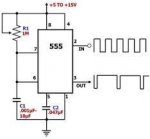

Can anyone give me some guidance on the above please ? Perhaps a filter circuit on the pulse input.

Paralleling the pulse tap onto the normal tacho input has not disrupted the normal rev counter display.

The convertor is this device 2x Frequency to Voltage Converter Module 0-1KHZ Frequency to 0-10V Voltage | eBay

Thanks.

I am using a Pulse to Analogue convertor rated for 0 - 1 kHz to 0 - 10vdc, and have roughly worked out that at max display revs of 3,000 RPM to expect a pulse frequency ~ 750 hz.

But when I run the engine at idle ~ 750 RPM I am seeing close to max revs voltage ~ 10vdc, and not the voltage I would expect ~ 2.5vdc

Going back to basics I need to know the Pole pair (N + S) quantity and Pulley ratio.

So can anyone tell me the common pole count for a typical ~ 90a marine duty alternator - or specifically as in my case as fitted to Cummins 6BT5.9M engines. Lots of general information available on alternators, but nowhere does it state the specifics of how many poles. I can strip the alternator and count the pole tabs on the rotor, but prefer not to do this.

6 seems to be fairly standard, but possibly 5 or even 8. None of these values explain why I am seeing such a high output.

I can work out the pulley ratio from the OD measurement of each pulley, but even this detail is not listed anywhere. My guestimate is based upon a Pulley ratio of 2.5 and a Pole count of 6.

I have found out the voltage to expect on the signal pulse is ~16 volts ac (RMS) so a peak value ~23vac. I am wondering if the signal is simply too strong or too noisy and is why I am seeing a corrupted output.

Can anyone give me some guidance on the above please ? Perhaps a filter circuit on the pulse input.

Paralleling the pulse tap onto the normal tacho input has not disrupted the normal rev counter display.

The convertor is this device 2x Frequency to Voltage Converter Module 0-1KHZ Frequency to 0-10V Voltage | eBay

Thanks.