wixlandia

New Member

We are re-doing the portlights/fixed windows on a 1980 fiberglass yacht manufactured by Cheoy Lee. All were leaking at the time of purchase, and seemed to have some kind of ancient putty various sealants applied at the margins.

She has two window types - fixed portlights in the main cabin, and opening portholes of anodized aluminium design.

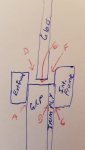

The former are installed in a 'sandwich' configuration with a profile cross-section in the attached image, with the glass captive between external and internal wooden frames that are attached to the margins of the cutout, but the glass is not unfortunately not directly compressed against the hull in any position. The internal ply fascia has been replaced, and sealed to the GRP with butyl tape. The wooden frames have been completely stripped and redressed. The glass has been replaced.

At this time, just the internal frames are installed, with butyl tape at B and C, and no signs of leak from B or C at all.

The glass can be placed in the cutout, but sits pretty loosely and the space between external frame (when dry fitted) and glass at D and internal frame and glass at F is quite large about 4mm on both sides - i.e. the window is not compressed in place by the frames. Our initial intention was to bed the window with butyl but a temporary fitment with butyl at E and F, without the external frames yet applied (shown in the picture taken from inside the cabin) has the window glass slumping to the bottom, and rain already in between glass and internal frame at F.

I figure we need to end up with some kind of gasket style seal bridging D, E and F with the external frame providing some moderate level of compression - but the butyl seems too gooey to do this.

Current plans involve using pieces of butyl tape as 'stand offs' at E to keep the window settled, then copious butyl sealant at F E and D and then maybe butyl tape or PE tape applied to the inner lip of the external frame at D to try to get some gasket style compression... it's not beautiful .

We could use a polyurethane sealant, but it'll be so hard to remove or repair in future - and we were keen to find a butyl solution.

Any help much appreciated.

She has two window types - fixed portlights in the main cabin, and opening portholes of anodized aluminium design.

The former are installed in a 'sandwich' configuration with a profile cross-section in the attached image, with the glass captive between external and internal wooden frames that are attached to the margins of the cutout, but the glass is not unfortunately not directly compressed against the hull in any position. The internal ply fascia has been replaced, and sealed to the GRP with butyl tape. The wooden frames have been completely stripped and redressed. The glass has been replaced.

At this time, just the internal frames are installed, with butyl tape at B and C, and no signs of leak from B or C at all.

The glass can be placed in the cutout, but sits pretty loosely and the space between external frame (when dry fitted) and glass at D and internal frame and glass at F is quite large about 4mm on both sides - i.e. the window is not compressed in place by the frames. Our initial intention was to bed the window with butyl but a temporary fitment with butyl at E and F, without the external frames yet applied (shown in the picture taken from inside the cabin) has the window glass slumping to the bottom, and rain already in between glass and internal frame at F.

I figure we need to end up with some kind of gasket style seal bridging D, E and F with the external frame providing some moderate level of compression - but the butyl seems too gooey to do this.

Current plans involve using pieces of butyl tape as 'stand offs' at E to keep the window settled, then copious butyl sealant at F E and D and then maybe butyl tape or PE tape applied to the inner lip of the external frame at D to try to get some gasket style compression... it's not beautiful .

We could use a polyurethane sealant, but it'll be so hard to remove or repair in future - and we were keen to find a butyl solution.

Any help much appreciated.