RunAgroundHard

Well-Known Member

Masthead rig, single spreader, shrouds, lower forward and aft stays, inner forestay, additional aft shrouds for inner forestay, 10mm stainless wire rigging.

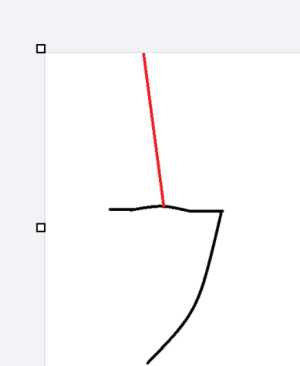

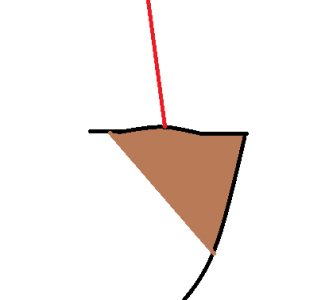

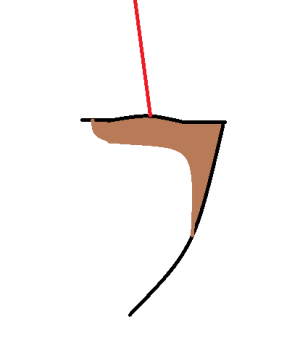

My lower forward shroud eye is an integral forged eyelet, shoulder, 1” threaded part that passes through the deck. Under the deck is the associated nut and 3mm thick washer about 2” OD. The deck at the penetration consists of the deck shelf mounded from the hull, with the deck and coach roof moulding sitting on the shelf. It’s around 1 1/2” thick. The deck is bonded to the shelf with an Epiphanes epoxy.

There is a bulge on the deck, some spider cracks in the gel coat and an associated depression on the underside of the coach roof, good access. There is no core here, just GRP layup.

I am planning on fitting a plate under the deck to butt against the side of the hull, about 200mm long, 100mm wide and 5mm thick. It will be drilled to take the threaded part of the eyelet, obviously, and epoxy used to create a fair surface and bond between the plate and deck.

My initial plan is to use stainless, but there is also G10 Epoxy Glass Laminate

Compressive strength G10 450 MPa

Yield strength A4 Stainless cold worked about 450 MPa. (YS is a reasonable comparison for CS in this case)

The stainless option could be bought as a channel section, the G10 can be easily shaped to conform to the hull.

If going for G10, do you think I should go to 10mm thick, shape and bond to the underside from hull conforming to the hull curve, also easy to add webs onto the hull. Or just go for a section of stainless U as big as I can fit, 100x50x5mm channel section by 200mm long.

My lower forward shroud eye is an integral forged eyelet, shoulder, 1” threaded part that passes through the deck. Under the deck is the associated nut and 3mm thick washer about 2” OD. The deck at the penetration consists of the deck shelf mounded from the hull, with the deck and coach roof moulding sitting on the shelf. It’s around 1 1/2” thick. The deck is bonded to the shelf with an Epiphanes epoxy.

There is a bulge on the deck, some spider cracks in the gel coat and an associated depression on the underside of the coach roof, good access. There is no core here, just GRP layup.

I am planning on fitting a plate under the deck to butt against the side of the hull, about 200mm long, 100mm wide and 5mm thick. It will be drilled to take the threaded part of the eyelet, obviously, and epoxy used to create a fair surface and bond between the plate and deck.

My initial plan is to use stainless, but there is also G10 Epoxy Glass Laminate

Compressive strength G10 450 MPa

Yield strength A4 Stainless cold worked about 450 MPa. (YS is a reasonable comparison for CS in this case)

The stainless option could be bought as a channel section, the G10 can be easily shaped to conform to the hull.

If going for G10, do you think I should go to 10mm thick, shape and bond to the underside from hull conforming to the hull curve, also easy to add webs onto the hull. Or just go for a section of stainless U as big as I can fit, 100x50x5mm channel section by 200mm long.