NealB

Well-Known Member

My coolant circulation pump has now been overhauled, with a spares kit from parts4engines.

I spent a couple of rather frustrating hours this afternoon, trying to refit it.

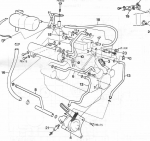

You might not be that surprised to hear that I'm having problems getting the copper pipes (8, 12 and 13 in the pic below) to sit firmly in their ports.

Any inside knowledge would be welcome.

eg is it better to push the pipes into their respective pump ports first, and then worry about connecting the other ends (to the block and heat exchanger), or the other way round?

eg Would you advocate using some sort of jointing compound to help the seal?

eg is it better to bolt the pump and its bracket to the block before trying to push in the pipes, or should I push in the pipes, and then fit the pump/ bracket?

To this non-engineer, the 'sprung' type of connection system seems as barmy as it is annoying.

I spent a couple of rather frustrating hours this afternoon, trying to refit it.

You might not be that surprised to hear that I'm having problems getting the copper pipes (8, 12 and 13 in the pic below) to sit firmly in their ports.

Any inside knowledge would be welcome.

eg is it better to push the pipes into their respective pump ports first, and then worry about connecting the other ends (to the block and heat exchanger), or the other way round?

eg Would you advocate using some sort of jointing compound to help the seal?

eg is it better to bolt the pump and its bracket to the block before trying to push in the pipes, or should I push in the pipes, and then fit the pump/ bracket?

To this non-engineer, the 'sprung' type of connection system seems as barmy as it is annoying.

Last edited: