sfellows

Well-Known Member

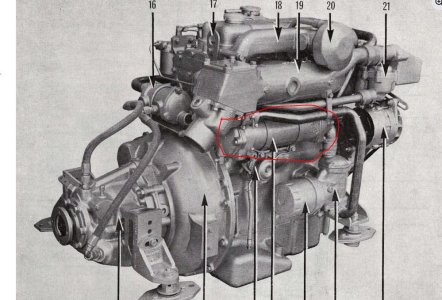

After previous recent posts, we've determined that our failed lowline M90 Heat Exchanger is no longer available and our options appear to be limited for a replacement. Has anyone replaced their Heat Exchanger for the combined Perkins M90 Bowman Exhaust/Header/Heat Exchanger Kit? If so what was your experience?

It's also been suggested that we Sikaflex the end-cap (which is warped and leaking as well as the aluminium housing facing being corroded) but the engineer won't do this as he said the Sikaflex will then block the heat exchanger. Any thoughts?

It's also been suggested that we Sikaflex the end-cap (which is warped and leaking as well as the aluminium housing facing being corroded) but the engineer won't do this as he said the Sikaflex will then block the heat exchanger. Any thoughts?