asteven221

Well-Known Member

Hi folks.

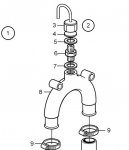

Can anyone advise me on the correct orientation of the nut assembly that has two threads i.e. the bit that joins the the main body to the outlet pipe? If you look closely the threads are different lenghts and slightly different profiles. Unfortunately it fits either way but there is obviously a correct way, that the dumpling (me) who took it apart has forgotten.

It is the anti syphon valve on a Volvo D2-55.

Thanks.

Can anyone advise me on the correct orientation of the nut assembly that has two threads i.e. the bit that joins the the main body to the outlet pipe? If you look closely the threads are different lenghts and slightly different profiles. Unfortunately it fits either way but there is obviously a correct way, that the dumpling (me) who took it apart has forgotten.

It is the anti syphon valve on a Volvo D2-55.

Thanks.