onesea

Well-Known Member

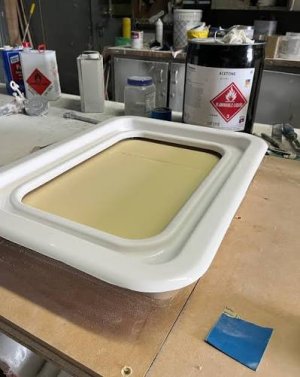

Looking for a filler for a hatch opening, that hasn't been cut.

The boat cockpit has inlays for hatches to be cut for cockpit lockers. However she had 1/4 berths instead and although moulded they where never cut.

The mouled inset created dips like that above (but without the middle cut out), that have been filled with plywood. However water gets ruined and underneath and then comes out when sailing, a surprisingly amount.

Is there an affordable filler ideally not too heavy I can use to replace the plywood, that will not absorb water and stop it pooling.

To create a smooth finish, this will be covered by teak effect decking or deck grip paint.

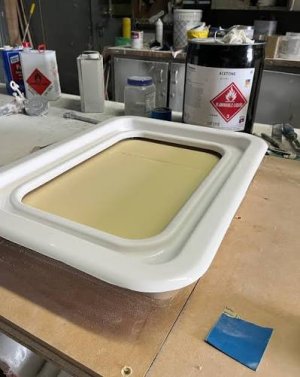

The boat cockpit has inlays for hatches to be cut for cockpit lockers. However she had 1/4 berths instead and although moulded they where never cut.

The mouled inset created dips like that above (but without the middle cut out), that have been filled with plywood. However water gets ruined and underneath and then comes out when sailing, a surprisingly amount.

Is there an affordable filler ideally not too heavy I can use to replace the plywood, that will not absorb water and stop it pooling.

To create a smooth finish, this will be covered by teak effect decking or deck grip paint.