weaver_fish

Well-Known Member

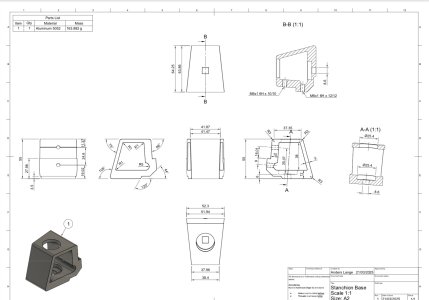

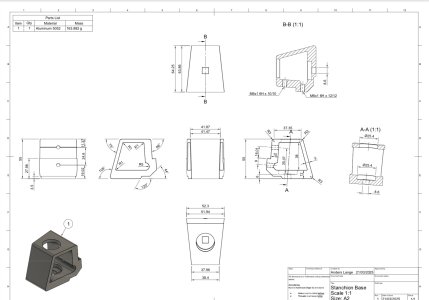

Has anyone with an engineering background got some advice

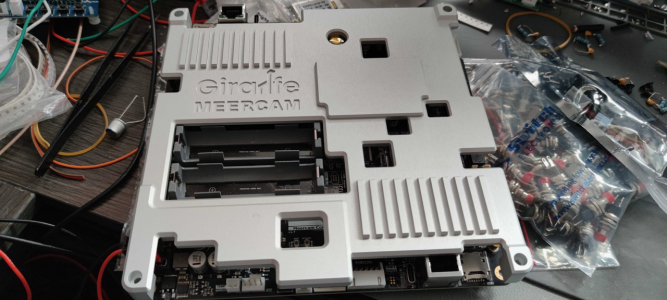

(1) any company who might be able to machine a series of stanchion bases as per the pics / drawing

(2) what sort of price we might expect to pay for eight

Many thanks - my sister ship owner has tried ringing around places with no success

I’m very much not an engineer but I think we can get the drawing files electronically from our helpful Swedish owner who created the drawing

Many thanks

(1) any company who might be able to machine a series of stanchion bases as per the pics / drawing

(2) what sort of price we might expect to pay for eight

Many thanks - my sister ship owner has tried ringing around places with no success

I’m very much not an engineer but I think we can get the drawing files electronically from our helpful Swedish owner who created the drawing

Many thanks