cpedw

Well-Known Member

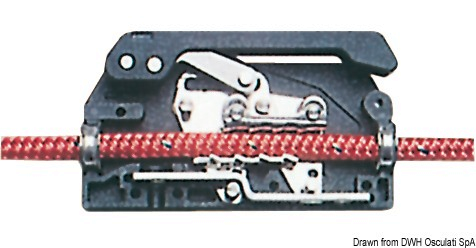

This Easylock Midi clutch (12mm main halyard) is prone to jamming itself when I'm at the mast (the clutch is at the cockpit) pulling the sail down. I think a loop of the halyard gets under the lever and pushes it up enough to jam. Then I have to return to the cockpit with the sail part lowered to release the clutch then back to the mast to continue the lowering.

Do you have any tips that might prevent this? Perhaps a clip or a weight to keep the lever in place?

Do you have any tips that might prevent this? Perhaps a clip or a weight to keep the lever in place?