ean_p

Well-known member

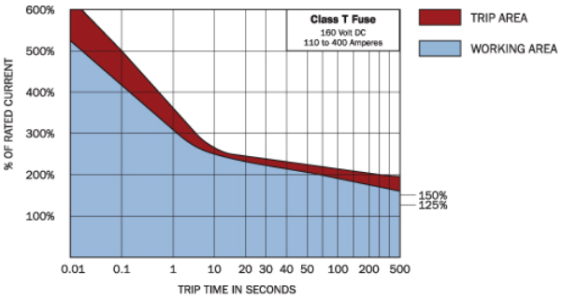

I know that in the US a T class fuse is the recommended fuse for 'short' protection on a Lithium battery but looking at the curves I wonder what parameters other Lithium users have applied when it comes to selecting the rating of the fuse?

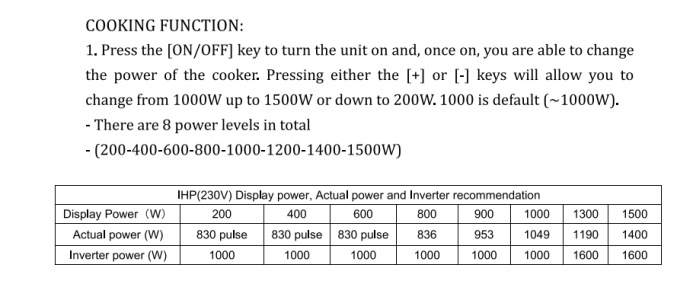

IE say for example 100ah battery which when used on an inverter may see 1.5C discharge therefore maybe a 150a T class fuse would be selected but that fuse might easily carry 300/400+ amps for several minutes thereby jeopardising the cabling connected to the battery. A sustained though possibly damaging discharge of 3C is not beyond question. Or is the approach a second in line fuse protective to the cable that may well be breached in the event of a direct short across the battery ?

Or is this all tosh thinking?

IE say for example 100ah battery which when used on an inverter may see 1.5C discharge therefore maybe a 150a T class fuse would be selected but that fuse might easily carry 300/400+ amps for several minutes thereby jeopardising the cabling connected to the battery. A sustained though possibly damaging discharge of 3C is not beyond question. Or is the approach a second in line fuse protective to the cable that may well be breached in the event of a direct short across the battery ?

Or is this all tosh thinking?