Kelpie

Well-Known Member

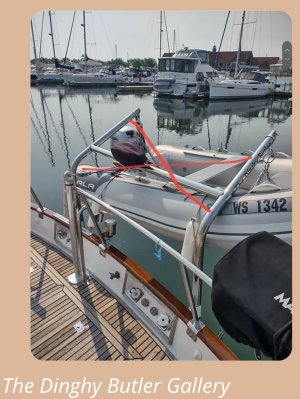

My davits are made from 50mm tubing and the way they are designed, are free to rotate in their mounting sockets.

I'd like to fit a bracing strut to triangulate it to the pushpit, but I'll need to think of a way to join the 25mm strut to the 50mm tube. The attachment will have to be able to pivot in order to get the right angle.

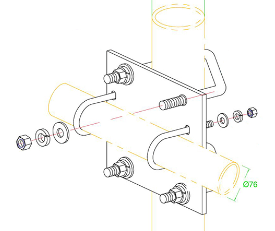

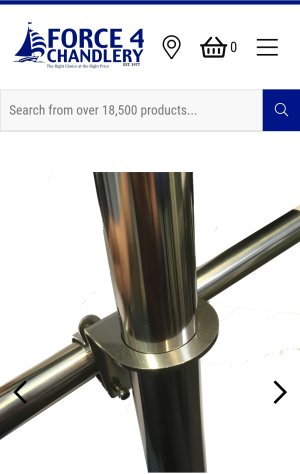

Best I can come up with is to fit an eye end cap on the strut, and thenuse one of these:

STAINLESS TUBE FORK MOUNTING. FOR END EYES.

and carefully grind it to be a better fit on the 50mm tube. Will be a bit fiddly to fit though.

Can anybody think of a better way?

I'd like to fit a bracing strut to triangulate it to the pushpit, but I'll need to think of a way to join the 25mm strut to the 50mm tube. The attachment will have to be able to pivot in order to get the right angle.

Best I can come up with is to fit an eye end cap on the strut, and thenuse one of these:

STAINLESS TUBE FORK MOUNTING. FOR END EYES.

and carefully grind it to be a better fit on the 50mm tube. Will be a bit fiddly to fit though.

Can anybody think of a better way?