pcatterall

Well-known member

We had an ongoing issue with the twist and lock on our Jabsco toilet. I changed/cleaned the rubber flap valve thingy many times.

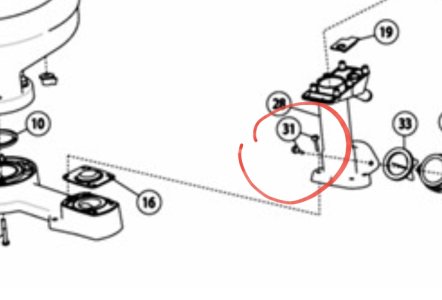

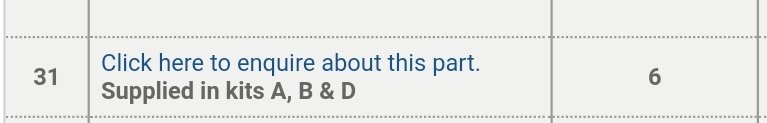

I realise, now that it was not the valve itself that leaked but due to one of the 4 screws that hold the pump to the base being ineffective.

The screw does not bite into anything and as a consequence after a bit of use water can seep around where the valve seats into the base.

3 screws seem to be holding it ok at the moment but I would like to get a fourth one in! The first few threads seem to have stripped in the 'plastic' base although there are threads

further down the hole. Possibly a longer screw would find purchase on these threads. If that fails I am not sure of what the best solution would be,. Possibly I could drill right through the base and screw to the timber below

( would this leak?) fill the hole with epoxy and drill out and fix a new screw ? what tap would be suitable for these type of screws?

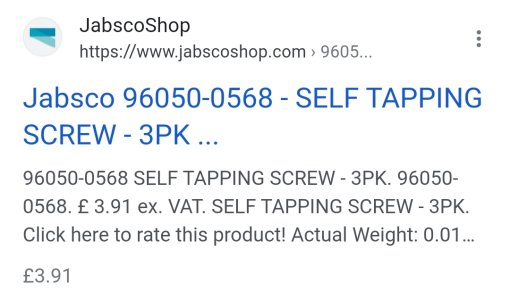

I attach a pic of the screw, does this kind of thread have a name? would it 'self' tap if a suitable hole was drilled?

Your usual good advice appreciated as always.

I realise, now that it was not the valve itself that leaked but due to one of the 4 screws that hold the pump to the base being ineffective.

The screw does not bite into anything and as a consequence after a bit of use water can seep around where the valve seats into the base.

3 screws seem to be holding it ok at the moment but I would like to get a fourth one in! The first few threads seem to have stripped in the 'plastic' base although there are threads

further down the hole. Possibly a longer screw would find purchase on these threads. If that fails I am not sure of what the best solution would be,. Possibly I could drill right through the base and screw to the timber below

( would this leak?) fill the hole with epoxy and drill out and fix a new screw ? what tap would be suitable for these type of screws?

I attach a pic of the screw, does this kind of thread have a name? would it 'self' tap if a suitable hole was drilled?

Your usual good advice appreciated as always.