ProDave

Well-known member

We have just taken delivery of our new boat, a Hunter Horizon 23 so this will be the first post of many as we knock it into shape.

The first question is we want a high power 2 pin in line plug and socket.

It has a Yamaha 8hp outboard in a well, and of course it would not start. So we removed it from the boat yesterday to bring it home to work on. But to remove it from the boat was harder than it needed to be as it has a pair of thick DC wires from the battery (it is electric start) and there was nowhere to disconnect them easily apart from unbolting both of them inside the engine, and to do that I had to disconnect at the battery. (Yes lots of electrical upgrades needed.)

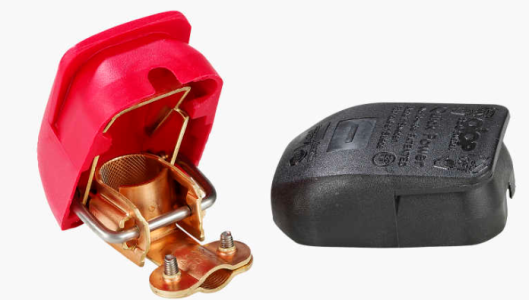

So the first question is I am looking for an in line 2 pin plug and socket to make disconnecting of the DC cable to the outboard a simple matter of unplugging it.

At the moment I can only think of forklift truck battery connectors but they are way bigger than needed, so hoping someone will know of something more suited to this application?

The first question is we want a high power 2 pin in line plug and socket.

It has a Yamaha 8hp outboard in a well, and of course it would not start. So we removed it from the boat yesterday to bring it home to work on. But to remove it from the boat was harder than it needed to be as it has a pair of thick DC wires from the battery (it is electric start) and there was nowhere to disconnect them easily apart from unbolting both of them inside the engine, and to do that I had to disconnect at the battery. (Yes lots of electrical upgrades needed.)

So the first question is I am looking for an in line 2 pin plug and socket to make disconnecting of the DC cable to the outboard a simple matter of unplugging it.

At the moment I can only think of forklift truck battery connectors but they are way bigger than needed, so hoping someone will know of something more suited to this application?