Lightwave395

Well-Known Member

I've just replaced the engine mounts on my Yanmar 3YM30, apart from skinned knuckles it went pretty well and the engine runs very smoothly.

I do have a problem however (or a challenge...), I can't see why but the net result is that at the lowest level rear mount adjustment setting, the gearbox flange is about 10mm above the prop shaft flange. The new mounts have 'settled' a couple of mm but nothing like enough to successfully align the shaft.

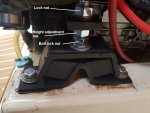

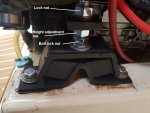

My initial thought is the basis of my question to any engineers out there - reference the picture is it safe / feasible to replace the full nuts that fix the bolt lock nut and the adjustment nut under the mounting bracket with 'half nuts' which would likely give me the 10 mm lowering movement I need ?

The adjustment bolts on the old rear mounts were both tightly down to their lowest positions.

This engine replaced a 3GM30 three years ago which as far as I can see is exactly the same dimension. The shaft alignment had previously been done with the boat out of the water and I recall the engine guy saying it had been a real pain to do and as it's a 30 year old boat I guess there has probably been some hull movement compared to it being done as it is now whilst in the water.

This is one of three solutions I can think of at this point, the other two being removing the adjustment nut altogether and using packing washers instead (this would be a PITA as it would potentially mean removing the mount and bracket perhaps several more times - a masochistic solution...) the other solution would be to have new mounting brackets fabricated with the mounting holes 10mm higher (they are simple brackets but this would be expensive)

Picture below - this is of the front mount, for clarity, where adjustment amount seems adequate, can't get a clear pic of the rears but the two nuts in question are tight together

Any thoughts or lateral thinking much appreciated, the boat is in France so 'popping down' and trying something is a little inconvenient !

I do have a problem however (or a challenge...), I can't see why but the net result is that at the lowest level rear mount adjustment setting, the gearbox flange is about 10mm above the prop shaft flange. The new mounts have 'settled' a couple of mm but nothing like enough to successfully align the shaft.

My initial thought is the basis of my question to any engineers out there - reference the picture is it safe / feasible to replace the full nuts that fix the bolt lock nut and the adjustment nut under the mounting bracket with 'half nuts' which would likely give me the 10 mm lowering movement I need ?

The adjustment bolts on the old rear mounts were both tightly down to their lowest positions.

This engine replaced a 3GM30 three years ago which as far as I can see is exactly the same dimension. The shaft alignment had previously been done with the boat out of the water and I recall the engine guy saying it had been a real pain to do and as it's a 30 year old boat I guess there has probably been some hull movement compared to it being done as it is now whilst in the water.

This is one of three solutions I can think of at this point, the other two being removing the adjustment nut altogether and using packing washers instead (this would be a PITA as it would potentially mean removing the mount and bracket perhaps several more times - a masochistic solution...) the other solution would be to have new mounting brackets fabricated with the mounting holes 10mm higher (they are simple brackets but this would be expensive)

Picture below - this is of the front mount, for clarity, where adjustment amount seems adequate, can't get a clear pic of the rears but the two nuts in question are tight together

Any thoughts or lateral thinking much appreciated, the boat is in France so 'popping down' and trying something is a little inconvenient !

Last edited: