coopec

N/A

I am going to use 10 mm Dyneema Rope as the cable in my chain/cable steering.

If I splice the ends of the rope at the quadrant, the rope diameter will be too large for the grooves in the quadrant (which are 10 mm).

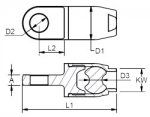

Why can't I use Dyneema Rope Terminals which surely would solve the problem? (I think attaching the Dyneema to the pedestal chain would be a better solution as well)

https://www.oceanchandlery.com/blue-wave-dyneema-rope-eye-terminal.html

https://jimmygreen.com/1200-bluewave-rope-terminals

I notice they say:

Safe working loads (SWL)

Blue Wave recommends that safe workloads should not to exceed one fifth (1/5) of the break loads listed.

But apparently that is engineering practice.

The SWL is determined by dividing the minimum breaking strength (MBS) of a component by a safety factor assigned to that type and use of equipment. ... For example, if a line has an MBS of 1,000 pounds and a safety factor of 5, then the SWL would be 200 pounds. 1000 / 5 = 200. Also called working load limit (WLL).

If I splice the ends of the rope at the quadrant, the rope diameter will be too large for the grooves in the quadrant (which are 10 mm).

Why can't I use Dyneema Rope Terminals which surely would solve the problem? (I think attaching the Dyneema to the pedestal chain would be a better solution as well)

https://www.oceanchandlery.com/blue-wave-dyneema-rope-eye-terminal.html

https://jimmygreen.com/1200-bluewave-rope-terminals

I notice they say:

Safe working loads (SWL)

Blue Wave recommends that safe workloads should not to exceed one fifth (1/5) of the break loads listed.

But apparently that is engineering practice.

The SWL is determined by dividing the minimum breaking strength (MBS) of a component by a safety factor assigned to that type and use of equipment. ... For example, if a line has an MBS of 1,000 pounds and a safety factor of 5, then the SWL would be 200 pounds. 1000 / 5 = 200. Also called working load limit (WLL).

Last edited: