Samoddie

New member

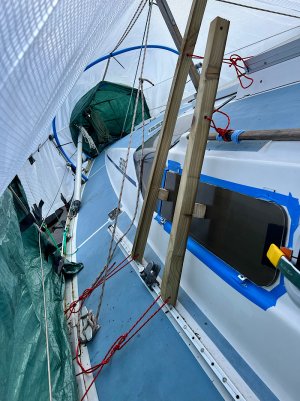

Am replacing the port lights in my Anderson 22 (yes, made of unobtainium, etc ). Did one in the summer, which was pretty hard, and took almost all day. I had refixed the frame, but stupidly hadn’t sealed the actual pane into the frame. So, frame was well fixed to the boat, and took an age to get off. All told, it took a day to do the one pane (my objective had really been to see how thick the acrylic was, but I wasn’t able to resist rebedding the pane and frame. Am expecting that one remaining frame will be as hard to get off, and the port side much easier cos they wont be at all well sealed once I have the fixings undone. The old acrylic was 4.5mm thick, and based on what I have read I have come to the view that 6mm will likely be fine (unsupported vertical span is perhaps 180mm). One reason I am not going for thicker is that the lights curve a little fore/ aft. My main question is - do I need to apply heat to allow this tiny bit of curve in the acrylic? Or, if the acrylic easily adapts to the shape, will it fine to put the acrylic into the frame, and re bed this frame into the cabin side? Subsidiary questions - I used Sikaflex to both bed acrylic into frame and to seal the frame to the cabin side. On the other hand, it does seem as if people use either specialist butyl products, or even just plain butyl tape? Comments welcome on all these issues! The complicating factor is that I will be doing the work in Feb, on the W coast of Scottish Highlands so while it wont be freezing, it wont be warm. At least when I do the next 3 portlights, the boat wont be afloat!

). Did one in the summer, which was pretty hard, and took almost all day. I had refixed the frame, but stupidly hadn’t sealed the actual pane into the frame. So, frame was well fixed to the boat, and took an age to get off. All told, it took a day to do the one pane (my objective had really been to see how thick the acrylic was, but I wasn’t able to resist rebedding the pane and frame. Am expecting that one remaining frame will be as hard to get off, and the port side much easier cos they wont be at all well sealed once I have the fixings undone. The old acrylic was 4.5mm thick, and based on what I have read I have come to the view that 6mm will likely be fine (unsupported vertical span is perhaps 180mm). One reason I am not going for thicker is that the lights curve a little fore/ aft. My main question is - do I need to apply heat to allow this tiny bit of curve in the acrylic? Or, if the acrylic easily adapts to the shape, will it fine to put the acrylic into the frame, and re bed this frame into the cabin side? Subsidiary questions - I used Sikaflex to both bed acrylic into frame and to seal the frame to the cabin side. On the other hand, it does seem as if people use either specialist butyl products, or even just plain butyl tape? Comments welcome on all these issues! The complicating factor is that I will be doing the work in Feb, on the W coast of Scottish Highlands so while it wont be freezing, it wont be warm. At least when I do the next 3 portlights, the boat wont be afloat!