All_at_Sea

Well-Known Member

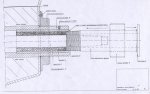

Having spoken to Contest in Holland they have a special tool (too heavy to post or lend) that can remove a cutlass bearing with the shaft in place. It goes over the shaft and screws into the metal of the bearing sleeve and then you hammer it out with a collar attached to this device. Very clever but does anyone have one in the UK?

I'm in Portsmouth so in need of an engineer that can do this without dropping the rudder. Any suggestions for possible engineers in the neighbourhood?

I'm in Portsmouth so in need of an engineer that can do this without dropping the rudder. Any suggestions for possible engineers in the neighbourhood?