Tintin

Well-Known Member

I've got one of those volvo penta control panels with the sealed 4 light block for oil pressure, alternator and water alarm.

And of course it is buggered (tech term).

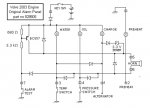

I have the circuit diagram of what is inside the potted block. It all seems complicated to me.

I am assuming the oil pressure and water temp sensor close circuit to engine negative when either event occurs.

How feasible do those wot know a lot more about such things think it would be to diy a panel with seperate light and piezo sounder for each?

Alternativel, would other volvo control panels work - i appreciate I would have to butcher the cabling a bit.

It seems the super expensive replacement part 873737 is out of stock everywhere.

And of course it is buggered (tech term).

I have the circuit diagram of what is inside the potted block. It all seems complicated to me.

I am assuming the oil pressure and water temp sensor close circuit to engine negative when either event occurs.

How feasible do those wot know a lot more about such things think it would be to diy a panel with seperate light and piezo sounder for each?

Alternativel, would other volvo control panels work - i appreciate I would have to butcher the cabling a bit.

It seems the super expensive replacement part 873737 is out of stock everywhere.